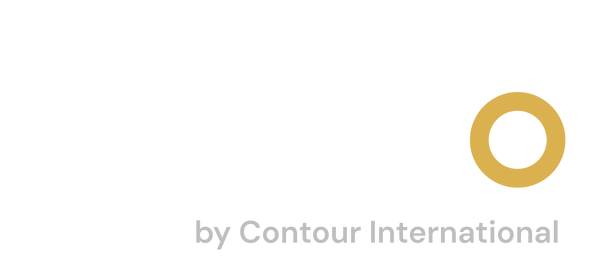

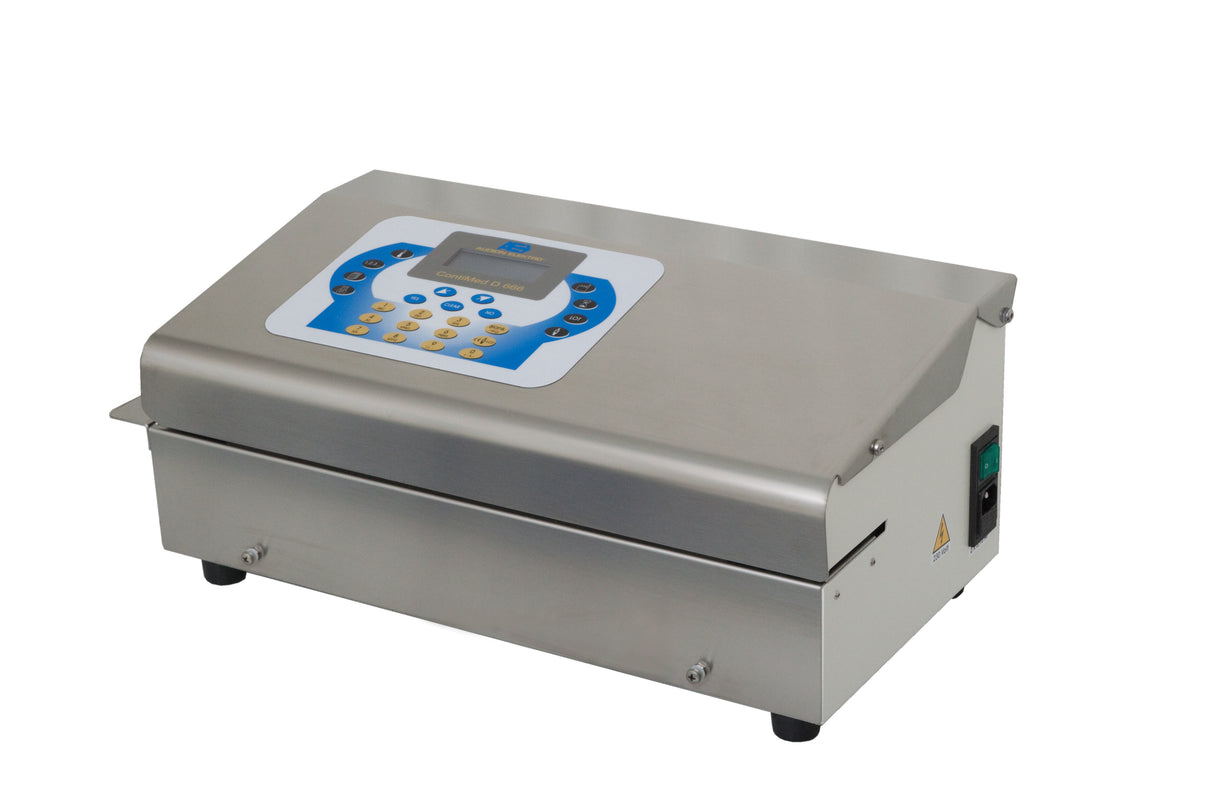

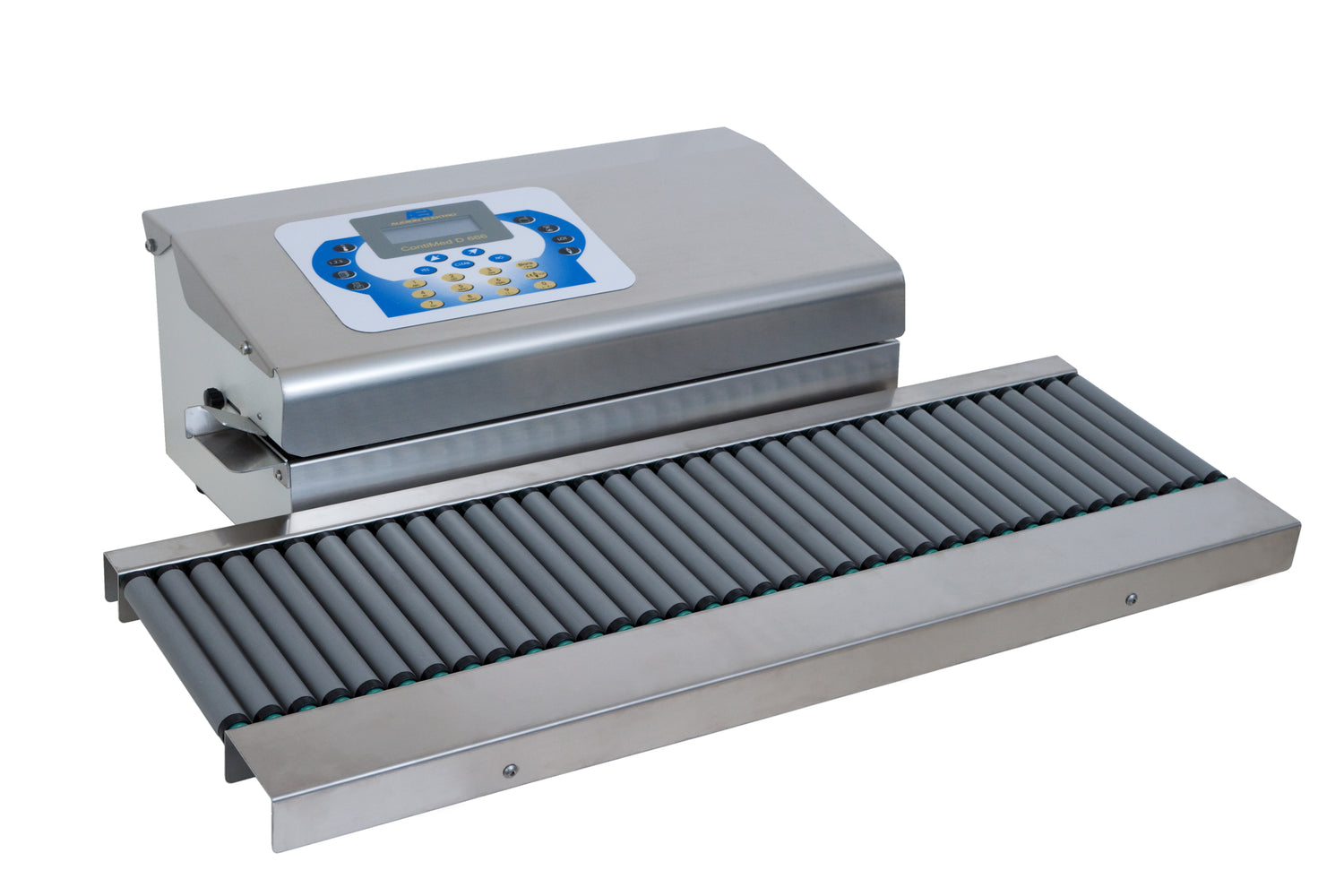

Audion Contimed D 666 MPCV Validatable Rotary Sealer Integrated 9dots Matrix Printer

Enquire now

For enquiries about multiple products use our Quote feature, no login necessary!

Single Product Enquiry: Audion Contimed D 666 MPCV Validatable Rotary Sealer Integrated 9dots Matrix Printer

Effortlessly Seal & Trace with Unmatched Precision

Audion Contimed D 666 MPCV is a high-performance rotary heat sealer is manufactured to reliably seal diverse sterilization pouches, including paper/PP, aluminum/PE, pre-formed sterile barrier systems, and uncoated Tyvek® (not suitable for single plastic films like PE, PP). The 15mm multiline seal is fully monitored and controlled (with alarm stop) across seal temperature, seal speed and seal force; with throughput at 10mtr/minute.

Key Features:

-

Uncompromising Validation

- Consistent 15mm multiline seals with precise control over seal temperature, speed, and force.

- Integrated alarm system with ±1% temperature accuracy ensures compliance with EN 868-5 and DIN 58953-7.

- Fully compliant with ISO 11607-2 and ISO/TS 16775 validation requirements.

-

Superior Traceability

- Integrated 9-dot matrix printer imprints essential production data: date, expiry, operator, batch code, seal temperature, force, speed, and pouch ID.

- Optional extra label printer for simultaneous labeling.

USB port for easy data storage and analysis.

-

High-Speed Performance

- Achieve rapid throughput of up to 10 meters per minute.

- Ideal for both delicate and heavy-duty packaging operations.

-

User-Friendly Design

- Intuitive digital display and membrane keypad for simple operation and minimal training.

- Alarm stop function with ±5°C tolerance for enhanced safety

Unmatched Reliability Consistent, high-quality seals with every use.

Manufactured in the Netherlands

Specifications

| Product Code | D666 MPCV |

| Machine Type | Band sealer, Semi automatic |

| Model | Tabletop |

| Seal Width | 15 mm Multiline seal |

| Seal Temperature | 0 - 200 °C (accuracy: +/- 1%) |

| Seal Temperature Alarm | Setting range 0-200 °C; Tolerance +/-5°C; Accuracy +/-1% |

| Throughput Speed | 10 meter/minute (fixed) |

| Seal Speed Tolerance | Min. 9.3 meter/min - Max. 10.5 meter/min |

| Seal Force | Min. 80 N - Max. 120 N |

| Seal Length | Unlimited |

| Control Panel | Membrane keyboard with keys and buzzer, LC display with 2 lines for 16 characters |

| Communication Interface | COM port RS232 / USB port |

| Housing | Epoxy housing, stainless steel top cover |

| Knife | No |

| Film Types | Medical Pouches: paper/PP, Tyvek®, Paper bags (EN 868-4), aluminum laminate, PA/PE, PP (OPP/BOPP), no single PE! |

| Film Thickness | 2x 100 micron |

| Compatibility | ISO 11607-2 / ISO/TS 16775 / EN 868-5 / DIN 58953-7 |

| Type of Pack | Bag, Pouch |

| Pedal operated | No |

| Weight | 20kg |

| Dimensions | 222 (H) x 554 (W) x 270 mm (D) |

| Power Supply | 115/230 V – 1 P – 50/60 Hz |

| Power Use | 600 W |

| Noise Level | <70 (dB(A) |

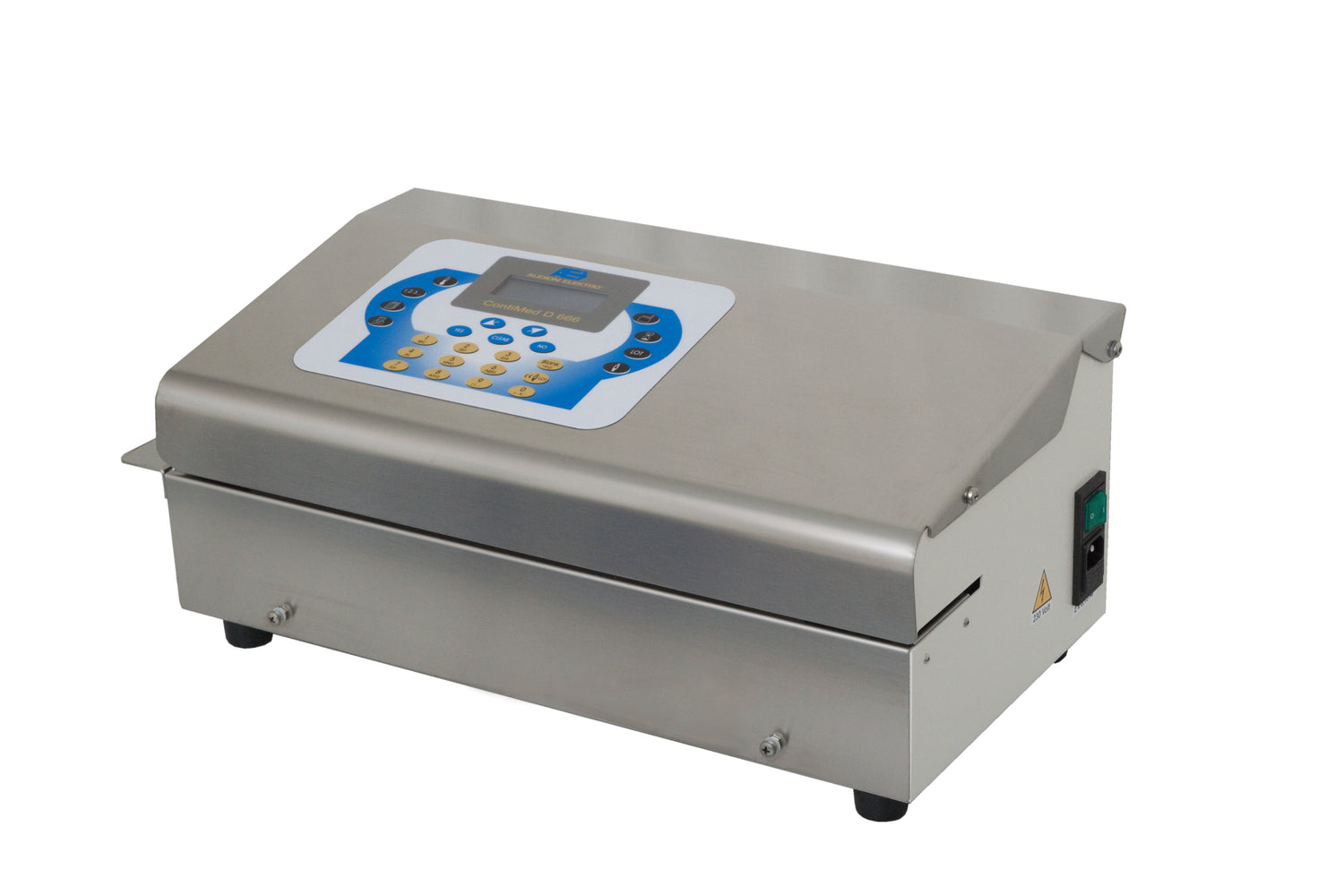

| Options Include | Worktable, Roller-table, Label Printer, Barcode scanner, |

Benefits

Validatable

Full control of all critical process parameters.

Adjustable seal temperature

Seal temperature can be adjusted from 0 - 200°C (± 1% accuracy).

Safety and quality controlled

Temperature alarm (temperature accuracy ± 1%), temperature tolerance +/-5°C, pressure alarm tolerance +/-20 N (default), speed alarm tolerance - 0,7 m/min. /+0,5 m/min. (default).

Extra wide seal

Wide multiline seal (15 mm).

Automatic alarm stop

The machine stops automatically when sealing parameters are out of tolerance range.

Fast throughput speed

10 meter/min.

Adjustable infeed guide

Free edge over the seal 0-30 mm.

Integrated printer

9 dot matrix (1 line).

Wide connectivity

COM port RS 232 facilitates connection of extra label printer, bar code scanner or a PC.

Interface

Integrated USB port and RS 232 port allow recording and export of critical process parameter data.

HMI

LCD display (2 lines for 16 characters) with membrane keyboard and buzzer.

Stainless steel top cover

For hygienic cleaning.

Compact design

Ideal for tabletop packaging applications.

Easy-to-use

Requires minimal operator training.

Application

- Life science (Pharmaceutical, Medical, Healthcare)

- High-Tech (parts/components)

This machine is custom-configured and manufactured to order. As it is not held in stock, please contact us to confirm current lead times.